I just got this older remington 552 speedmaster earlier today and its missing the rear sight, barrel stamped W 7

Quick check of Remington mfg letter stamps puts this mfg July 1971?

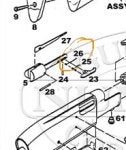

The Numrich parts schematic only shows two types, neither of which look like what may have been on this particular rifle.

The gun was given to a fellow because it wont feed, and he robbed the sight off it and gave me the rifle, from the looks of it, was someones old camp gun that got a face lift, stock looks like itd been sanded and finished and metal all looks like was spray painted (esp where the sight used to be) there is powder residue (soot) inside the spent case deflector so it must have developed feeding issue not long after its face lift.

So have to figure out why it wont feed and locate a replacement sight. It looks allot like a sight off a Model 550-1,512 511 510 Remington, if I were to locate a sight for one of those it should fit?

Quick check of Remington mfg letter stamps puts this mfg July 1971?

The Numrich parts schematic only shows two types, neither of which look like what may have been on this particular rifle.

The gun was given to a fellow because it wont feed, and he robbed the sight off it and gave me the rifle, from the looks of it, was someones old camp gun that got a face lift, stock looks like itd been sanded and finished and metal all looks like was spray painted (esp where the sight used to be) there is powder residue (soot) inside the spent case deflector so it must have developed feeding issue not long after its face lift.

So have to figure out why it wont feed and locate a replacement sight. It looks allot like a sight off a Model 550-1,512 511 510 Remington, if I were to locate a sight for one of those it should fit?